OLMEC

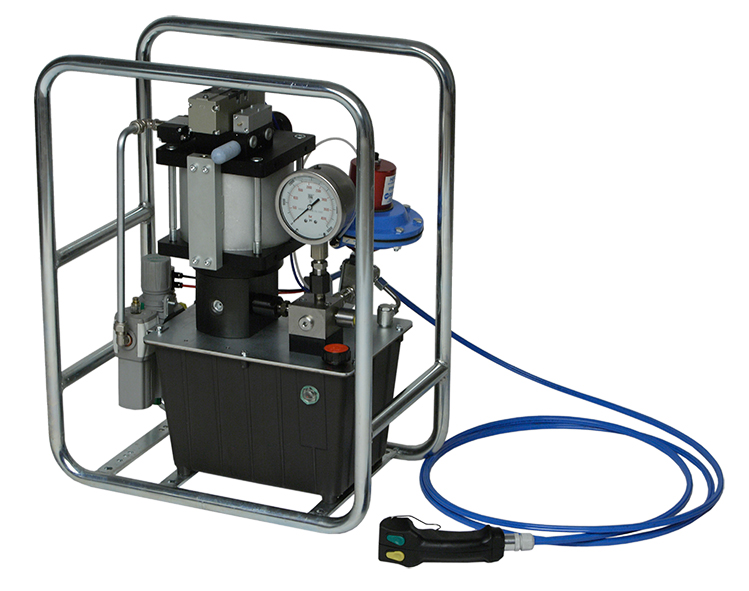

Olmec manufacture a comprehensive range of Air Powered Hydraulic Pumps, Air/Oil Boosters, Workholding Cylinders, and Pneumatic and Hydraulic Jacks.

Olmec Air Operated Pumps are used as a low cost, non-electrical solution to pressurize a hydraulic system with air-hydraulic intensification ratios ranging from 5:1 to 265:1.

Olmec Pumps are used to supply pressurized oil, emulsion or water circuits.

The pumps operate with a reciprocating motion, single acting or double acting, powered by a pneumatic control valve, that stops when the maximum hydraulic pressure is reached, maintaining the pressure in the circuit, without using any more air. If the hydraulic pressure drops, the pump is automatically restarted to restore the pre-set hydraulic conditions.

Hydraulic tests on seals with oil or water. |

Supply of cylinders for clamping, assembly and maintenance equipment. |

Fixed or mobile emergency work units, oil or grease lubrication systems. |

All environments with an explosion risk |

Laboratory testing. |

For more information on OLMEC products CLICK HERE to contact us.